Project Description

-

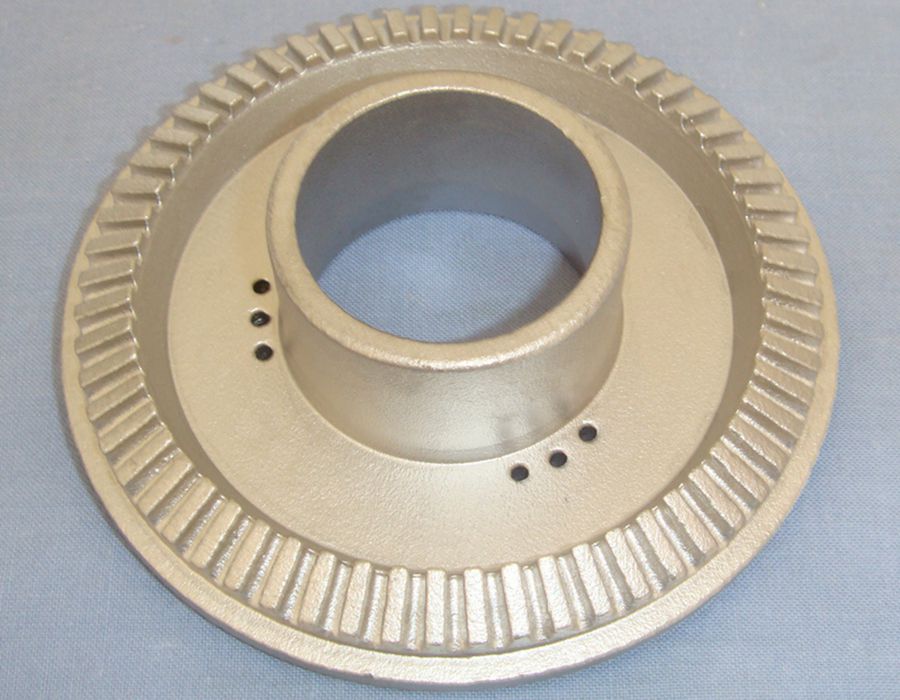

Material:carbon steel, stainless steel, alloy steel

-

Weight: 20g to 30kg

-

Typical tolerance: DIN2768

-

Surface finish: Ra6.3

-

Surface treatment: black oxide, powder coating, zinc plating, ect.

-

OEM/ODM: Available

-

Wax patterns making

-

Wax patterns assembly

-

Shell making

-

Dewaxing

-

Burnout & preheating

-

Pouring

-

Gate removal

-

Shot blasting

-

Excellent surface finish

-

High dimensional accuracy

-

Extremely intricate parts are castable

-

Almost any metal can be cast

-

No flash or parting lines

-

Complying with the management system to meet all customer needs and regulatory requirements

-

Arranging production under the quality system

-

Inspection from raw material, during production, initial samples and mass production

-

In-house laboratory testing, including chemical composition analysis and mechanical properties inspection in a formal certification report

-

Non-destructive inspection, such as magnetic particle inspection, penetration inspection, and digital X-ray by third-party companies if required

-

An identification system for potential issues

-

Plating and coating

Anodizing, zinc, nickel, hard chrome plating, black oxide, e-coat, and other plating /coating services

-

Painting

Powder coat, prime, and other painting services

-

Polishing